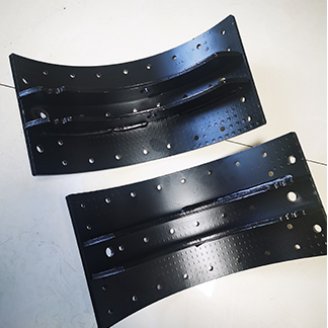

HeavyTruck Brake Shoe

20+ years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Sales volume (units) : 1,000,000+

Brake shoe: cylindrical grinding

Customized packaging:Acceptable

Truck brake shoes are an important part of your truck's braking system. Here is some key information about them:

1. Function: Brake shoes are part of a drum brake system and are common in heavy-duty vehicles such as trucks. When the brake pedal is pressed, hydraulic pressure pushes the brake shoes against the inner surface of the drum, creating friction that slows and stops the truck.

2. Construction: They are usually made of a heat-resistant friction material bonded or riveted to a metal backing plate. This friction material is designed to withstand the heat generated during braking and provide consistent performance over time.

3. Replacement: Brake shoes wear out over time due to the friction generated during braking. Regular inspection and replacement is essential to maintain braking efficiency and safety. Replacement intervals depend on factors such as driving conditions, loads and driving habits.

4. Maintence: Proper maintenance of brake shoes involves regular inspection of the braking system, including checking the thickness of the friction material and ensuring that the drums are within the specified tolerances. Any sign of wear or damage should be replaced immediately.

5. Safety: Maintaining the braking system, including the brake shoes, is critical to the safety of the truck and its occupants. Properly functioning brakes ensure reliable braking power and reduce the risk of accidents.

6. Professional Service: Due to the complexity of the brake system and the importance of proper installation, brake shoe replacement is usually done by a trained mechanic. It is recommended that brake shoes be replaced at a certified service center or by a qualified technician.

Replacements | Benz Mp31 Cast Mp32 Cast Mp36 Cast |

Brake sizes | 420×150 mm, 420×180 mm, 420×200 mm, 420×220 mm, 311×190 mm, etc. |

Colors | Red, black, grey, blue, etc. |

Optional parts | Brake lining, rivet, repair kit of brake shoe, etc. |

Package | Pallet. |

Standards implemented | IATF 16949, ISO9001-2015, JT/T 475-2020 |

Payment | TT, LC, DP |

Lead time | About 10~15 working days |

MOQ | 1 unit |

Application:

The brake shoe is the friction part of the drum brake, which bears the thrust of the actuator, the normal and tangential force of the brake drum and the support reaction force, and should have appropriate stiffness. In addition to the strength and stiffness required as a component, it should have the highest and most stable coefficient of friction possible, as well as appropriate abrasion resistance, heat resistance, heat dissipation and heat capacity.