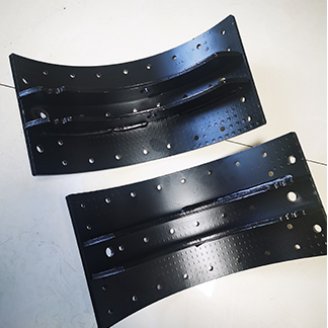

Semi Trailer Brake Shoes

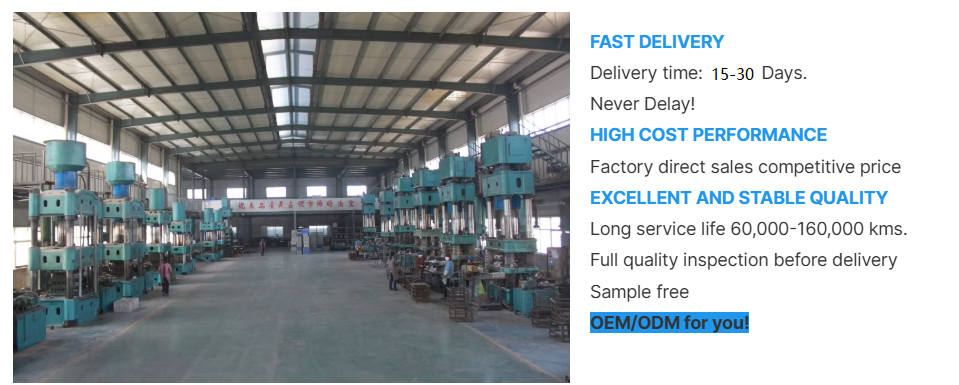

ISO 9001-2015 by an independent laboratory

Conduct quality testing Warranty: 12 months from the date of shipment

Sales volume (units): 1,000,000+

Brake shoes: Cylindrical grinding

Product description:

Organic brake shoes: mainly made of a mixture of organic materials such as carbon fiber, aramid fiber, and glass fiber. They have the advantages of smooth braking, low noise, and good comfort, but the disadvantage is that the wear resistance is relatively poor, and the braking performance will gradually decrease with the increase of use time and mileage.

Semi-metallic brake shoes: On the basis of organic materials, a certain proportion of metal powders, such as copper powder, iron powder, and aluminum powder, are added to improve the wear resistance and heat dissipation performance of the brake shoes. The braking performance is relatively high, but it may generate loud noise during braking, and the wear on the brake drum is relatively large.

Ceramic brake shoes: Made of ceramic materials, they have extremely high temperature resistance, good wear resistance, and stable braking performance. They can maintain good performance under high-speed braking and frequent braking. At the same time, they also have the advantages of low noise and less wear on the brake drum, but the cost is high and they are generally used in high-end models.

Product parameters:

Item no | B | R | Φ1 | Φ | A1+A2 | T1 | T2 | Dia.of Hole | No.of Hole |

XHBC/36/1 | 180 | 205 | Φ26.2 | Φ36.4 | 317.7 | 8 | 5 | Φ8.5 | 20 |

XH4515 | 180 | 203 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515E | 180 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515Q | 180 | 205 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551 | 220 | 205 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.7 | 32 |

XH4551E | 220 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551Q | 220 | 203 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4516 | 203 | 203 | Φ26.2 | Φ19.2 | 317.7 | 8 | 5 | Φ6.5 | 32 |

XHBZ-160 | 160 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-180 | 180 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-222 | 222 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XH4656 | 162 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.2 | 20 |

XH4657 | 220 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.4 | 18 |

XH4715 | 152 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 24 |

XH4728 | 220 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 32 |

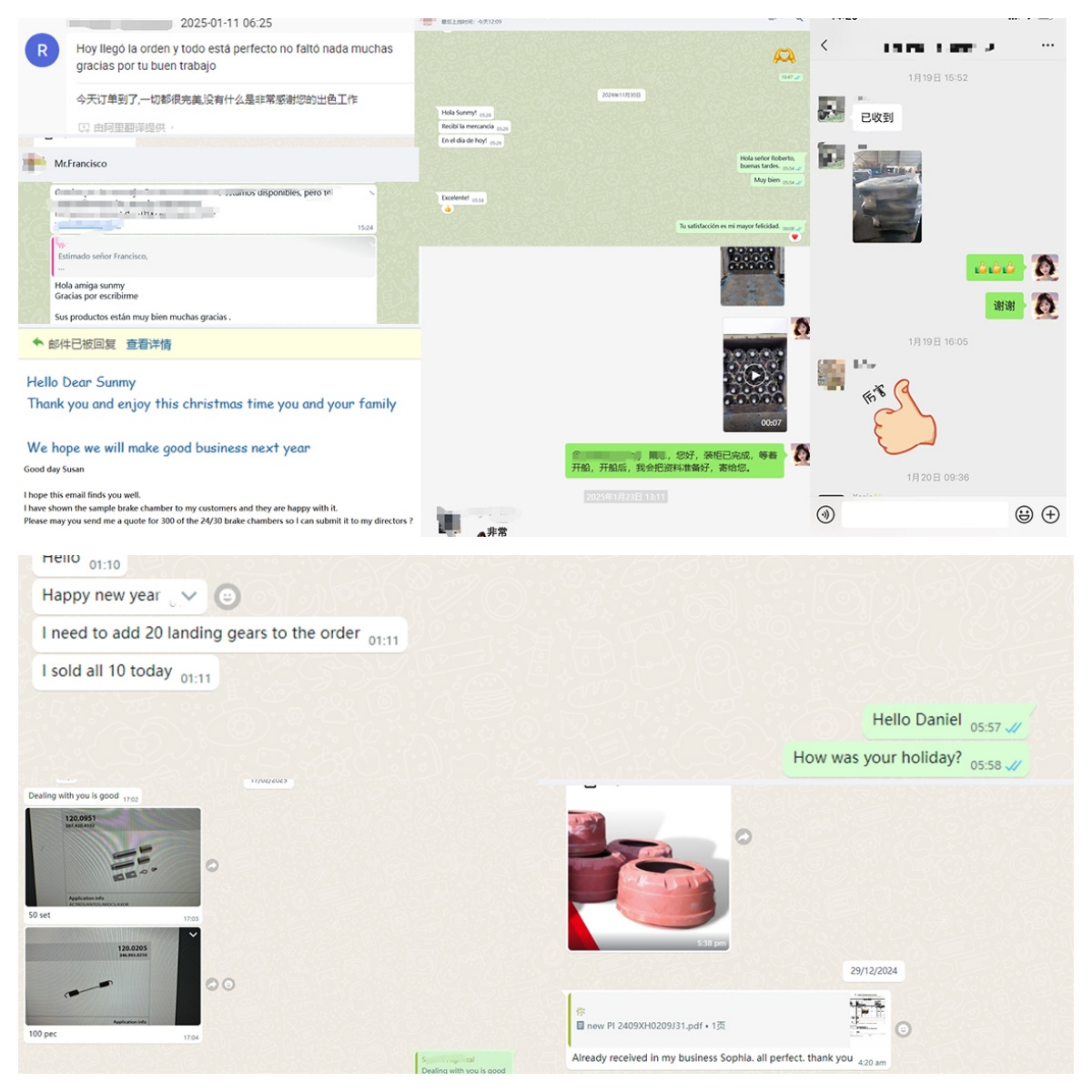

Our Customers' Feedback:

Our Service:

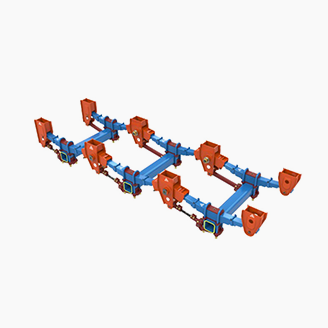

Application:

A brake shoe is the part of a braking system which carries the brake lining in the drum brakes used on automobiles, or the brake block in train brakes and bicycle brakes. A device that is put on a track to slow down railroad cars is also called brake shoe.

The brake shoe carries the brake lining, which is riveted or glued to the shoe. When the brake is applied, the shoe moves and presses the lining against the inside of the drum. The friction between lining and drum provides the braking effort. Energy is dissipated as heat.

The brake shoe is widely applied on axles of semi-trailers, full trailers, farm trailers, boat trailers and all trucks.

FAQ:

Q: Who are we?