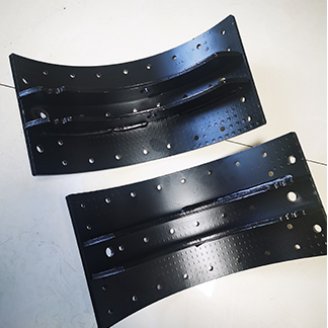

Semi Trailer Brake Shoe

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Sales volume (units) : 1,000,000+

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Brake shoe: cylindrical grinding

Customized packaging:Acceptable

Product description:

A semi trailer brake shoe is a component of the brake system in a semi trailer.

Technical parameters

Brake size: 16.5 inches in diameter.

Brake width: 7 inches.

Friction material grade load: 20,000 pounds or 23K grade (different products may vary).

Friction material connection method: Riveted.

Product parameters:

Item no | B | R | Φ1 | Φ | A1+A2 | T1 | T2 | Dia.of Hole | No.of Hole |

XHBC/36/1 | 180 | 205 | Φ26.2 | Φ36.4 | 317.7 | 8 | 5 | Φ8.5 | 20 |

XH4515 | 180 | 203 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515E | 180 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515Q | 180 | 205 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551 | 220 | 205 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.7 | 32 |

XH4551E | 220 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551Q | 220 | 203 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4516 | 203 | 203 | Φ26.2 | Φ19.2 | 317.7 | 8 | 5 | Φ6.5 | 32 |

XHBZ-160 | 160 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-180 | 180 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-222 | 222 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XH4656 | 162 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.2 | 20 |

XH4657 | 220 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.4 | 18 |

XH4715 | 152 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 24 |

XH4728 | 220 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 32 |

Application:

The application of semi trailer brake shoes involves installing them properly within the brake system of the trailer to ensure efficient and safe braking performance. Here is a general outline of the steps involved in the application of semi trailer brake shoes:

Safety first: Prior to starting any work on the brake system, make sure the trailer is securely parked on a level surface and the wheels are chocked to prevent it from rolling.

Remove the wheel: To access the brake shoes, the wheel and tire assembly will need to be removed. Loosen the lug nuts, raise the trailer with a jack, and securely support it with jack stands. Then, remove the wheel and tire assembly.

Access the brake assembly: Locate the brake drum on the trailer axle and remove any dust cover or inspection hole cover to access the brake assembly.

Remove old brake shoes: Use the appropriate tools to remove the retaining clips, pins, or springs that secure the old brake shoes in place. Take note of how the components are positioned before removing them to aid in reassembly.

Install new brake shoes: Position the new brake shoes in the same orientation as the old ones and secure them in place using the retaining clips, pins, or springs.

Reassemble the brake assembly: Reinstall any components that were removed to access the brake shoes, such as the dust cover or inspection hole cover.

Replace the wheel: Once the brake shoes are properly installed and the brake assembly is reassembled, reinstall the wheel and tire assembly onto the trailer.

Test the brakes: Lower the trailer off the jack stands, tighten the lug nuts, and test the trailer brakes to ensure they are functioning correctly.

It's essential to follow the manufacturer's guidelines and specifications for the specific make and model of your semi trailer when applying brake shoes to ensure proper installation and optimal brake performance. If you are not comfortable performing this task yourself, it is recommended to seek assistance from a professional mechanic or service center.

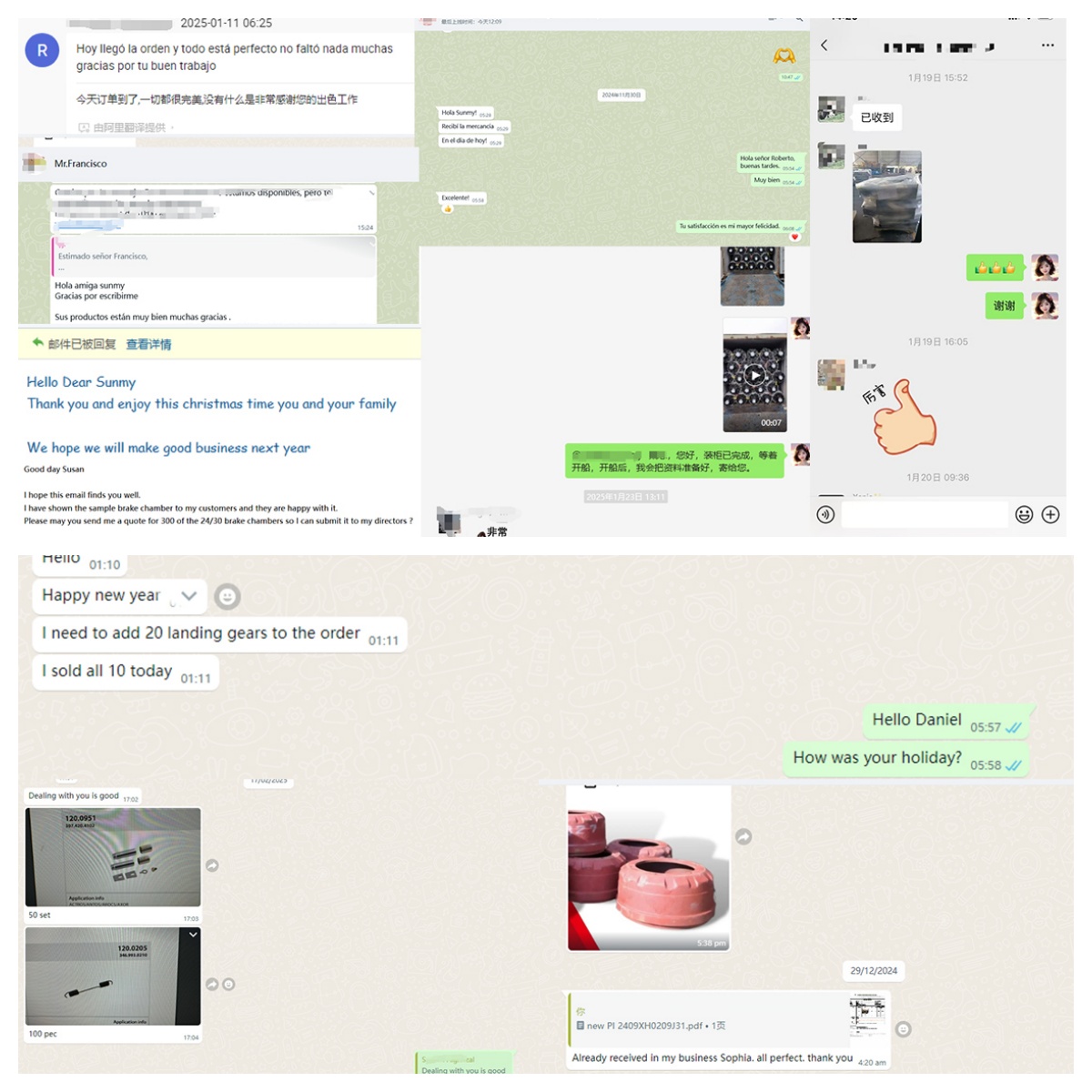

Our Customers' Feedback:

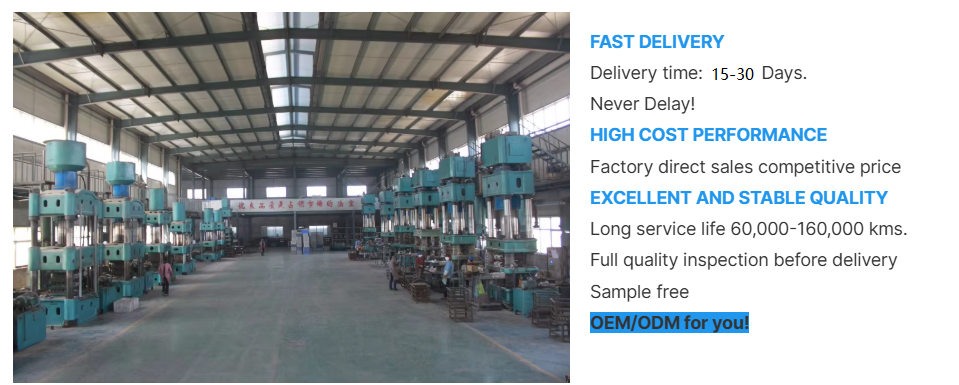

Our Service: