Semi Trailer Axle Low Bed Axle

20+ years of experiences (since 2005)

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Fatigue life: 1,700,000 cycles

Bearing position machining precision (Dia.): 0~0.025mm

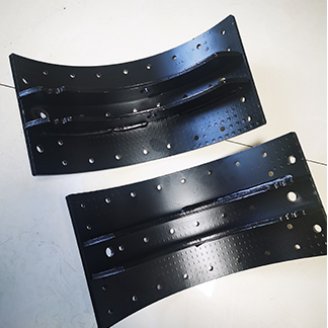

Brake shoe: cylindrical grinding

Both ends of the beam are processed at the same time

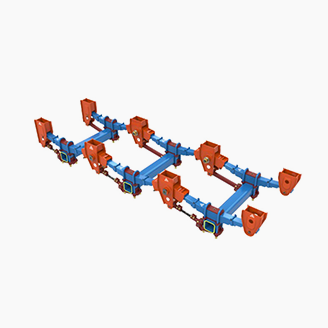

A low bed Trailer Axle is the main structural component of a low bed trailer on which the wheels and tires are mounted. The axle is responsible for helping to support the weight of the trailer and its cargo, as well as facilitating smooth, controlled movement on the road. Low bed trailers have a low deck height to allow for easy loading and unloading of tall or heavy equipment. The configuration of the axles on a low bed trailer may vary depending on the design and intended use of the trailer, with options for single, dual, or even multiple axles for efficient weight distribution.

Product parameters:

Axle Type | Max Capacity | Track | Brake | Centre Distance Seat(mm) | Axle Beam (mm) | Centre Distance Chamber (mm) | Wheel Fixing | Recom wheel | (kg) Axle Weight | Note | |||

Stud | D1P.C.D | D2 Hole Diameter | Total Length | ||||||||||

XH-10.5 | 12 | 1820 | 420*180 | ≥950 | o127 | 368 | 10*M22*1.5 | 285.75 | 221 | ~2165 | 7.5V-20 | 360 | Bearing(Inner) HM518445/10 HM518445/10 |

XH-10.5 | 12 | 1820 | 420*180 | ≥950 | o127 | 368 | 10*M22*1.5 | 335 | 281 | ~2165 | 7.5V-20 | 363 | |

XH-13 | 13 | 1840 | 420*180 | ≥930 | 150*150 | 388 | 10*M22*1.5 | 285.75 | 281 | ~2185 | 7.5V-20 | 363 | Bearing(Inner) HM518445/10 HM518445/10 |

XH-13 | 13 | 1840 | 420*180 | ≥930 | 150*150 | 388 | 10*M22*1.5 | 335 | 281 | ~2185 | 7.5V-20 | 370 | |

XH-15 | 15 | 1850 | 420*180 | ≥940 | 150*150 | 396 | 10*M22*1.5 | 335 | 281 | ~2185 | 8.0V-20 | 398 | Bearing(Inner) HM220149/10 HM518445/10 |

XH-16 | 16 | 1850 | 420*220 | ≥940 | o127 | 354 | 10*M22*1.5 | 335 | 281 | ~2185 | 8.00V-20 | 423 | |

XH-16 | 16 | 1850 | 420*220 | ≥940 | 150*150 | 354 | 10*M22*1.5 | 335 | 281 | ~2205 | 8.00V-20 | 425 | |

Application:

Low bed trailer axles play a vital role in the overall performance and functionality of a low bed trailer. Some of the key applications for low bed trailer axles include:

Load capacity: the axle is designed to effectively support and distribute the weight of the trailer and its cargo. Depending on the axle capacity and configuration, it determines how much weight the trailer can safely carry.

Maneuverability: Axles allow trailers to turn, swivel and swerve smoothly. Axle design (e.g., wheelbase and wheelbase) affects the trailer's maneuverability in tight spaces or challenging terrain.

Stability: Axles help keep trailers stable and balanced, especially when loading and transporting heavy equipment or machinery. Proper axle placement and alignment is critical for safe and reliable transportation.

Suspension: Axles are often integrated with suspension systems to absorb shock and vibration during travel, ensuring a smoother ride and reducing wear and tear on the trailer and its cargo.

Compatibility: Axles must be compatible with the overall trailer design and construction. Factors such as wheelbase, tire size and braking system integration are important considerations when choosing an axle for a lowboy trailer.

Overall, lowboy trailer axles are a critical component that affects the performance, safety and efficiency of the trailer in a variety of transportation applications.