Type 24 Brake Chamber

20+ years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality Standards: SAE J14659

Return spring:>2,000,000 cycles

Life-time: >1,000,000 cycles

Salt spray test: Passes 200 hours

Synthetic blended rubber diaphragms: Superior resistance against abrasion and fatigue cracking

Product Description:

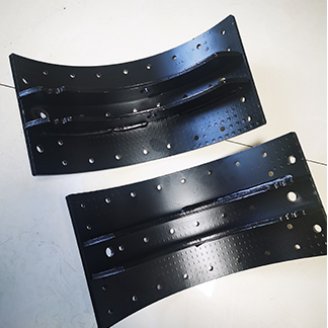

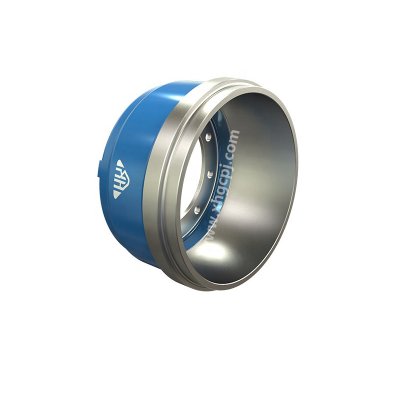

The brake air chamber is a device composed of an air inlet, a cover, a diaphragm, a support plate, a return spring, a housing, a push rod, a connecting fork, a clamp, and a bolt.

The brake air chamber is also called the brake cylinder. The function of the brake air chamber is to convert the pressure of the compressed air into the mechanical force that makes the brake camshaft rotate to realize the braking action. It is the executive element in the automobile air brake system and an important safety part on the automobile.

1. According to the function classification, there are single air chamber and double air chamber. The front and rear brake chambers of the dual air chambers are of different sizes, but their structures are basically the same.

2. According to the structure classification, there are membrane type and piston type. The brake air chamber is clamp clamping diaphragm type.

Parameters:

| Type | Stroke | R1 | R2 | L1 | L2 | Pushrod Thread Length L4 | Pushrod Thread | Air Inlet Thread | Mounting Bolt Thread | Mounting Inluded Angle | Weight |

| T-24 | 64 | 116 | 93 | 110 | 227 | 207 | 5/8"-18UNF2A | 3/8"-NPTF | 5/8"-1 1UNC2A | 45° | 4kgs |

| T-30 | 64 | 130 | 106 | 110 | 255 | 255 | 5/8"-18UNF2A | 3/8"-NPTF | 5/8"-1 1UNC2A | 45° | 4.6kgs |

| Type | Chamber Volume(Litre) (Measure Pressure:700kpa) | Parking Chamber Force Output (kn) | (Stroke:38mm) | Diaphragm | |||||||

| 400kpa | 700kpa | Working Area(SQ cm) | Dia.At Clamp Point (mm) | ||||||||

| T-24 | 1.08 | 5.58 | 9.8 | 141 | 161 | ||||||

| T-30 | 1.48 | 7.3 | 12.8 | 180 | 181 | ||||||

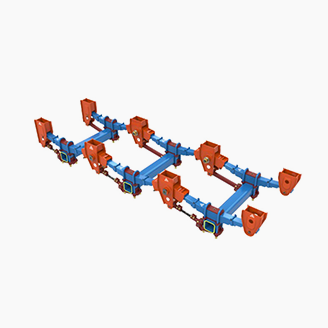

Applications:

The Type 24 brake chamber is a critical component of the braking system, working in conjunction with other components such as brake drums, shoes, and valves to bring the vehicle to a halt when the driver applies the brakes. Proper maintenance and adjustment of the brake chamber are essential to ensure optimal braking performance and safety during operation.