Semi Trailer Suspension Parts Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

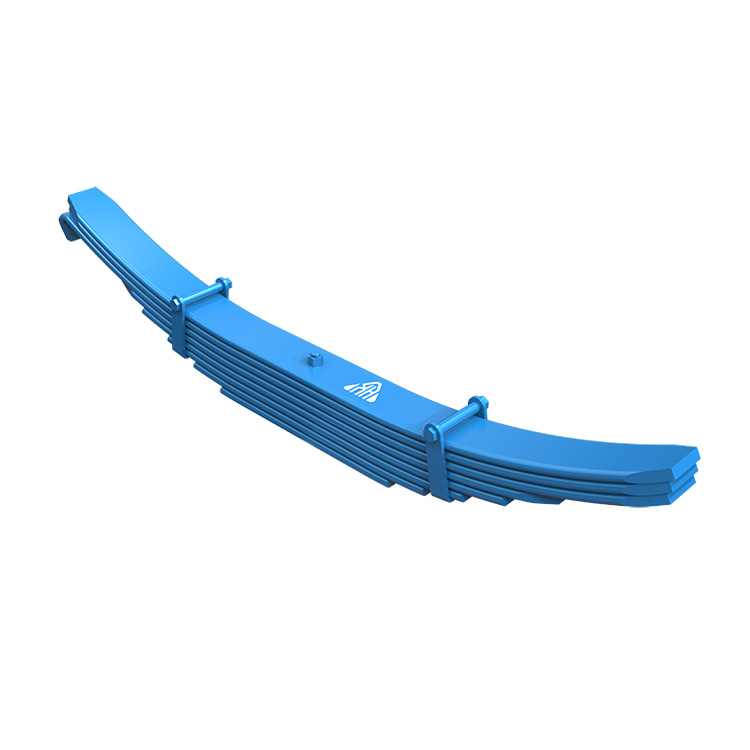

Leaf springs are a vital part of the suspension system for semi-trailers, providing crucial support and stability under heavy loads. Here’s an overview of how leaf springs function within the context of semi-trailer suspension, along with other related components:

Leaf Springs in Semi-Trailer Suspension:

Load Support: Leaf springs are primarily responsible for distributing the weight of the semi-trailer and its cargo across the axles. They absorb and manage the forces generated by the weight, ensuring that the trailer remains stable and balanced during travel.

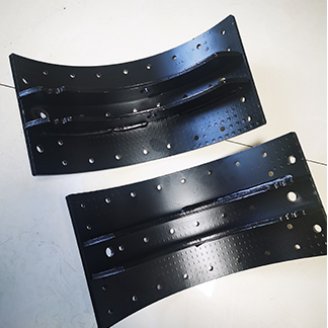

Types of Leaf Springs: Semi-trailers typically use multi-leaf springs due to their capacity to handle heavy loads effectively. These springs consist of several layers (or leaves) of tempered or hardened steel stacked on top of each other and held together with clamps or bolts. The number and thickness of these leaves can vary based on the trailer's weight rating and specific requirements.

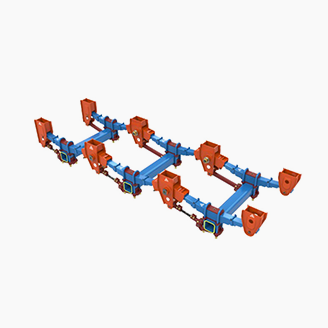

Suspension System Integration: Leaf springs work in conjunction with other suspension components such as shock absorbers, bushings, and axle connections. This integrated system helps to absorb road shocks and vibrations, providing a smoother ride for the driver and reducing wear and tear on the trailer.

Durability and Strength: Leaf springs are designed to withstand the rigorous conditions encountered in semi-trailer operations, including rough road surfaces, varying weather conditions, and frequent loading and unloading. They are constructed from high-strength materials to ensure durability and reliability over extended periods of use.

Maintenance: Regular inspection and maintenance of leaf springs are crucial to ensure optimal performance and safety. This includes checking for signs of wear, corrosion, proper lubrication, and ensuring that the springs are correctly aligned and adjusted according to manufacturer specifications. Timely replacement of worn-out or damaged leaf springs is essential to prevent safety hazards and maintain the trailer's operational efficiency.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

The application of leaf springs in semi-trailer suspension involves several key aspects that contribute to the functionality, reliability, and safety of the vehicle:

Functionality and Load Handling:

Load Distribution: Leaf springs are crucial for distributing the weight of the semi-trailer and its cargo across multiple axles. They help in evenly distributing the load to prevent excessive stress on any single axle, thereby maintaining stability and improving overall handling.

Support and Stability: Leaf springs provide robust support to the semi-trailer, ensuring it remains level and stable even when carrying heavy loads. This stability is essential for safe operation and maneuverability, especially during turns and over uneven road surfaces.

Application and Maintenance:

Durability and Maintenance: Leaf springs are designed to withstand the demanding conditions of commercial transportation, including rough roads and heavy loads. Regular inspection and maintenance are essential to ensure that leaf springs are free from wear, corrosion, and fatigue. Lubrication of moving parts and timely replacement of worn-out components are critical to maintaining optimal suspension performance and safety.

Customization: Leaf springs can be customized in terms of their thickness, number of leaves, and configuration to suit specific trailer designs and operational requirements. This customization allows manufacturers and operators to tailor the suspension system to achieve optimal load-carrying capacity, ride comfort, and durability.

In summary, leaf springs play a vital role in the suspension system of semi-trailers, providing essential load support, stability, and durability necessary for safe and efficient transportation of goods. Their integration with other suspension components ensures reliable performance across various operating conditions, contributing to the overall functionality and longevity of the semi-trailer.