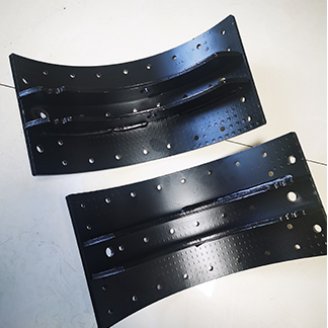

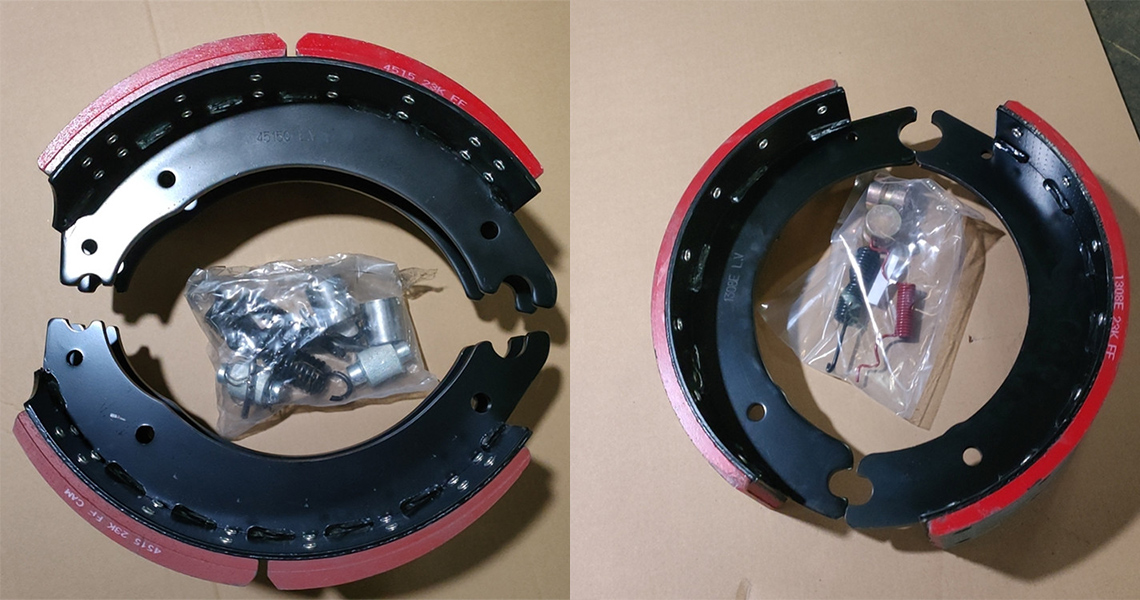

Brake Shoe for Trailer

20+ years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Sales volume (units) : 1,000,000+

Brake shoe: cylindrical grinding

Customized packaging:Acceptable

Product description:

When selecting brake shoes for a trailer, whether it's a utility trailer, boat trailer, camper trailer, or any other type of trailer, there are a few key factors to consider:

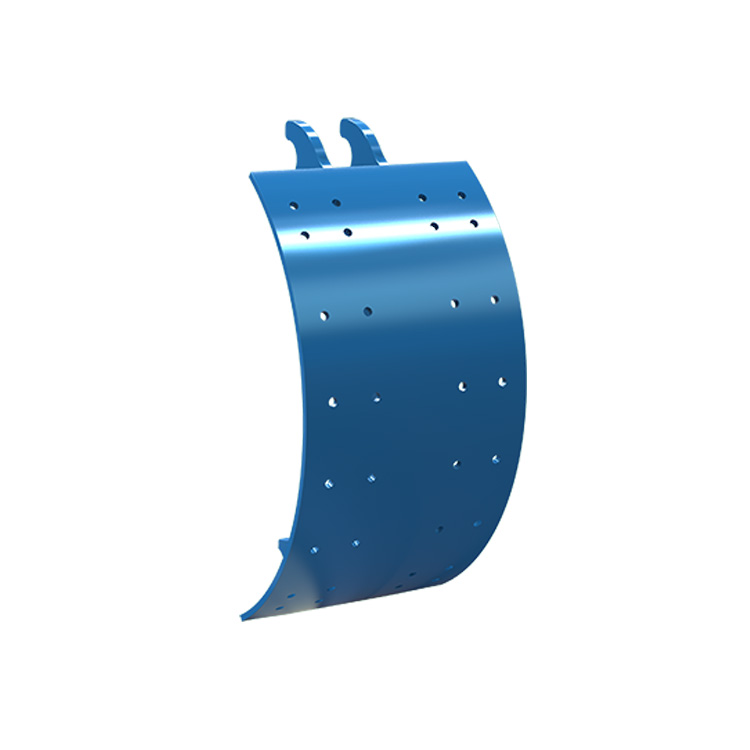

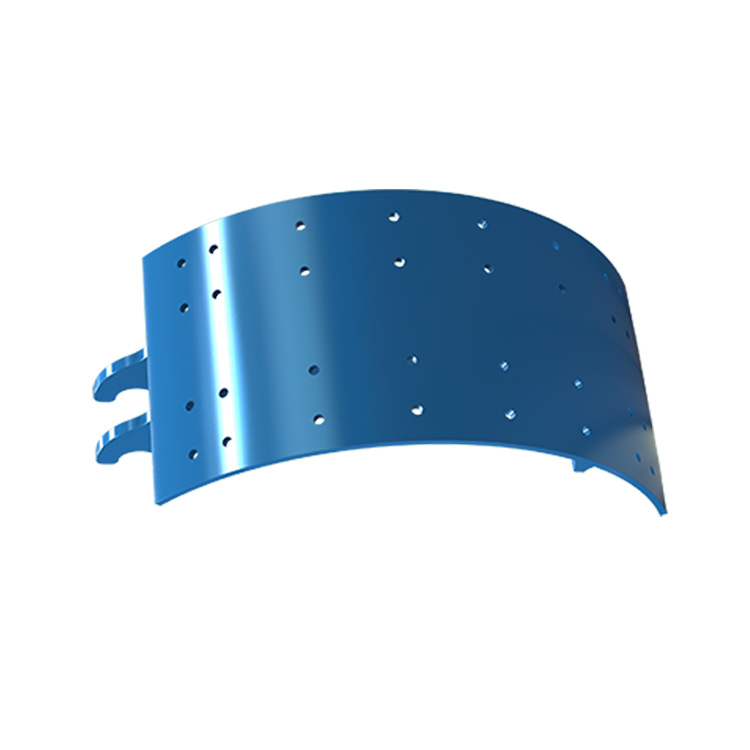

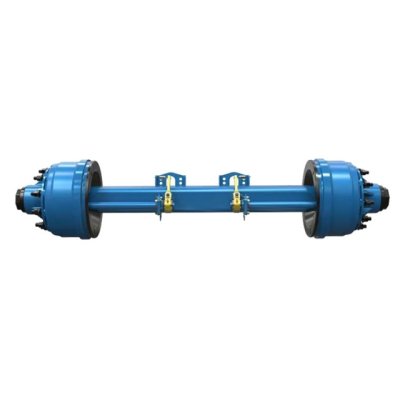

Size and Compatibility: It's essential to choose brake shoes that are the correct size and compatible with the braking system on your specific trailer. Ensure that the dimensions, mounting style, and hardware match the requirements of your trailer.

Brake System Type: Trailers typically use electric brakes, hydraulic brakes, or surge brakes. Make sure the brake shoes you select are designed for the specific type of braking system on your trailer to ensure proper functioning.

Weight Rating: Consider the weight capacity of your trailer to ensure the brake shoes can handle the load. Select brake shoes that are rated for the maximum weight your trailer can carry to maintain safe braking performance.

Material and Construction: Opt for high-quality brake shoes made from durable materials that can withstand the demanding conditions of towing. Ensure they are heat-resistant and built to provide reliable braking performance over time.

Brand Reputation: Choose brake shoes from reputable brands known for their quality and reliability. This can help ensure that you are getting a product that meets industry standards and will perform effectively.

Maintenance and Replacement: Consider factors such as ease of maintenance and replacement when selecting brake shoes for your trailer. Look for brake shoes that are user-friendly and come with clear installation instructions.

By considering these factors, you can choose the right brake shoes for your trailer to ensure safe towing and effective braking performance. If you're unsure about which brake shoes to select, consult your trailer's manual or a professional mechanic for guidance.

Product parameters:

Item no | B | R | Φ1 | Φ | A1+A2 | T1 | T2 | Dia.of Hole | No.of Hole |

XHBC/36/1 | 180 | 205 | Φ26.2 | Φ36.4 | 317.7 | 8 | 5 | Φ8.5 | 20 |

XH4515 | 180 | 203 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515E | 180 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4515Q | 180 | 205 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551 | 220 | 205 | Φ27.5 | Φ19.5 | 323.85 | 8 | 5 | Φ6.7 | 32 |

XH4551E | 220 | 203 | Φ27 | Φ19.1 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4551Q | 220 | 203 | Φ32 | Φ19.2 | 323.85 | 8 | 5 | Φ6.5 | 32 |

XH4516 | 203 | 203 | Φ26.2 | Φ19.2 | 317.7 | 8 | 5 | Φ6.5 | 32 |

XHBZ-160 | 160 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-180 | 180 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XHBZ-222 | 222 | 200 | Φ20.1 | Φ30 | 318.75 | 6 | 8 | Φ8.2 | 16 |

XH4656 | 162 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.2 | 20 |

XH4657 | 220 | 200 | Φ47 | Φ32 | 319 | 6 | 8 | Φ8.4 | 18 |

XH4715 | 152 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 24 |

XH4728 | 220 | 203 | Φ32 | Φ19.1 | 324 | 6 | 8 | Φ6.7 | 32 |

Application:

Brake shoes are a crucial component of a vehicle's drum brake system. They are curved metal plates lined with friction material, typically made of asbestos, ceramic, or other composite materials.

When the brake pedal is pressed, hydraulic pressure is applied to the wheel cylinder, causing the brake shoes to press against the inner surface of the brake drum. The friction material on the brake shoes creates resistance against the rotating drum, causing the wheel to slow down and eventually stop.

Brake shoes undergo significant heat and friction during braking, which can lead to wear over time. Regular maintenance and inspection of brake shoes are essential to ensure optimal braking performance and safety. If the brake shoes become worn out or damaged, they should be promptly replaced to maintain the effectiveness of the braking system.

In summary, brake shoes are an integral part of the drum brake system that work together to slow down and stop a vehicle by creating friction against the brake drum.